A major milestone has been reached at the Woodfibre LNG project in British Columbia, as the first large-scale modules arrived over the weekend, signalling the start of vertical construction at the site. The delivery marks a pivotal step in the development of what is set to become Canada’s first net-zero liquefied natural gas export terminal.

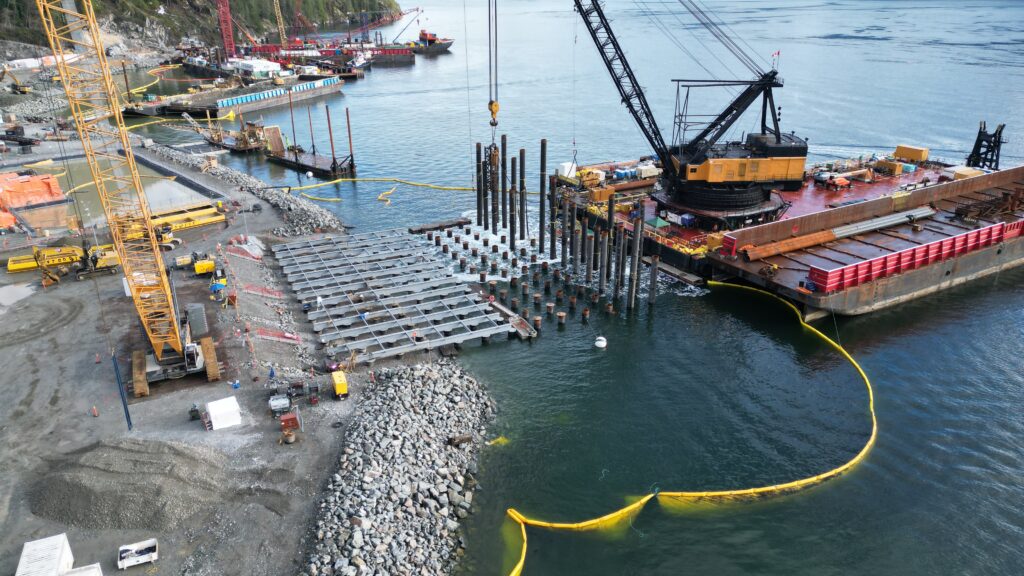

Seven massive pipe rack modules, specially engineered to support LNG piping infrastructure, were transported to the site via heavy-lift cargo vessel and are now being prepared for offloading at the newly built Marine Offloading Facility near Squamish. These prefabricated steel structures will eventually form the backbone of the system that moves liquefied gas between the plant’s liquefaction units and offshore storage and loading areas.

“This is a huge milestone for the Woodfibre LNG project as it’s the start of our facility going vertical, where people will really start to see the facility take shape,” said Luke Schauerte, CEO of Woodfibre LNG. “These first modules represent a tangible step toward diversifying Canada’s energy export portfolio while delivering long-term value for Canadians.”

The pipe racks are just the beginning. Over the next 18 months, 19 prefabricated modules will be shipped to the site in phases. They range in size and function, from 126-tonne pipe racks to a colossal 11,000-tonne liquefaction unit, the largest of the series, which will span an area roughly equal to a football field.

Once on site, the modules will be maneuvered into place and anchored to permanent foundations, marking the transition into full-scale construction. According to project leaders, this is the most visually dynamic and technically complex stage of development.

Located on the traditional lands of the Sḵwx̱wú7mesh Úxwumixw (Squamish Nation), the Woodfibre LNG project is breaking new ground in more ways than one. It is the first industrial development in Canada to formally acknowledge and empower a non-treaty Indigenous government as a full environmental regulator.

Slated for completion in 2027, the facility aims to produce 2.1 million tonnes of LNG per year for international export. But beyond its scale, the project is also charting a bold path in sustainability. Billed as the world’s first net-zero LNG export terminal, Woodfibre LNG will harness clean hydroelectric power from BC Hydro to drive its energy-intensive liquefaction process. Additional emissions will be addressed through carbon offset strategies.

“We’ve hit an incredibly exciting point in the project,” Schauerte added. “Over the coming months, the site will change dramatically. Our priority is keeping construction safe, on schedule, and true to our net-zero commitment.”

Owned by Woodfibre LNG Limited Partnership, a joint venture between Pacific Energy Corporation (Canada) Limited (70%) and Enbridge Inc. (30%)—the project is now entering its most active phase. Marine transport, heavy lifting, and precision engineering will define the site’s landscape through 2026 as module arrivals continue and assembly accelerates.

As global energy markets look for cleaner, more reliable sources of supply, Woodfibre LNG positions Canada as a serious contender, offering responsibly produced LNG with a significantly lower carbon footprint than many global competitors.

With construction now moving skyward, the next chapter in Canada’s LNG story is officially underway.