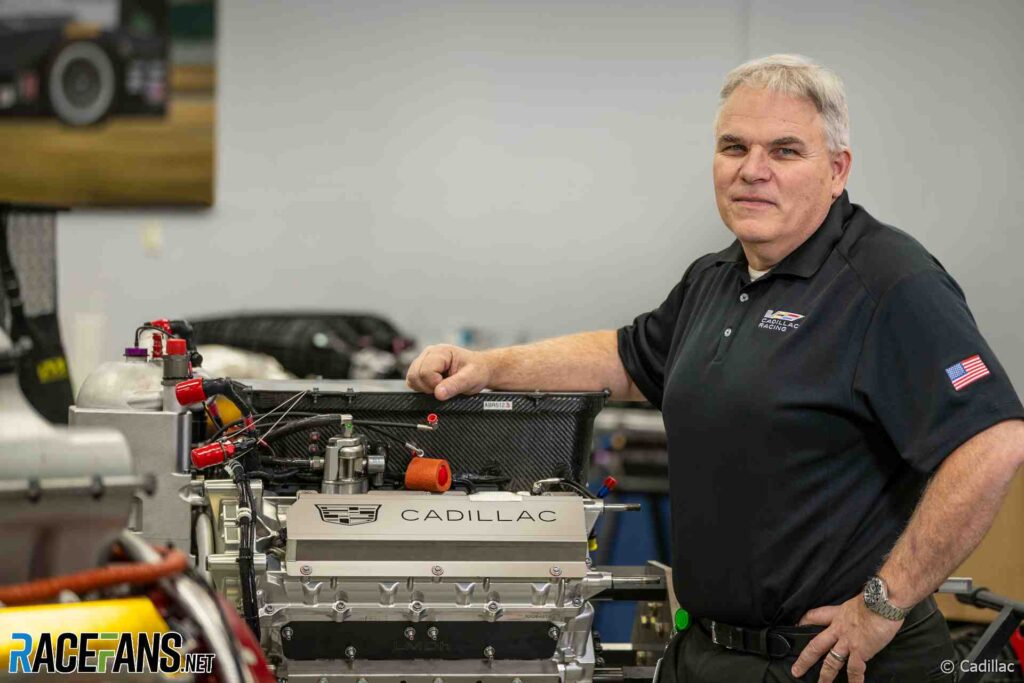

In an era dominated by headlines about electric vehicles, General Motors (GM) is making a bold and somewhat unconventional, move by doubling down on internal combustion technology. The automaker has announced a massive $888 million investment in its Tonawanda Propulsion Plant near Buffalo, New York, to produce its next-generation V-8 engines.

This initiative marks the single largest investment GM has ever made in an engine facility, reaffirming the company’s commitment to its gasoline-powered product lines even as it accelerates its electric vehicle (EV) ambitions.

The Tonawanda facility has been a cornerstone of GM’s engine production for nearly nine decades. Since opening its doors in 1938, the plant has built millions of engines for a wide variety of GM vehicles and currently employs over 1,500 skilled workers. With this new investment, the company plans to transform the site into a cutting-edge centre for the development of sixth-generation V-8 engines, designed for full-size trucks and SUVs, where performance and towing capacity remain top priorities for consumers.

While the remodel is underway, the plant will continue producing GM’s fifth-generation V-8 engines, ensuring uninterrupted supply for key vehicle lines.

GM’s announcement comes at a pivotal moment in the auto industry. With governments and consumers increasingly focused on sustainability and emissions reduction, automakers are under pressure to scale up electric vehicle production. Yet, demand for powerful gasoline engines, especially in North America, remains strong, particularly among buyers of heavy-duty trucks, commercial vehicles, and performance SUVs.

“While our long-term future is electric, we recognise the continued importance of combustion engines in today’s market,” said GM Chair and CEO Mary Barra. “This investment ensures we continue to provide world-class propulsion systems that our customers trust, while also supporting good-paying American manufacturing jobs.”

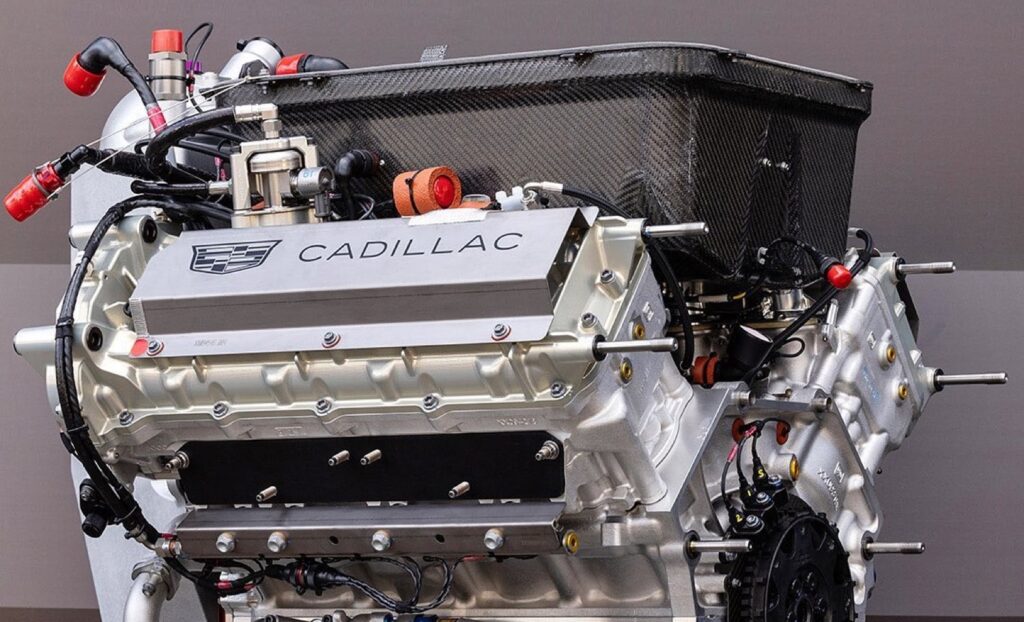

Barra emphasised that the sixth-generation engines will incorporate advanced technologies to boost fuel efficiency, reduce emissions, and deliver higher performance, demonstrating that combustion engines can still evolve to meet modern expectations.

The $888 million outlay will fund state-of-the-art tooling, machinery, and plant renovations to support future production. Beyond modernising the facility, the investment is expected to secure and potentially grow jobs in Western New York, an important signal of GM’s ongoing commitment to its U.S. workforce amid global competition and supply chain volatility.

State and local officials welcomed the news, highlighting the project’s potential to revitalise the region’s manufacturing base and reinforce Buffalo’s reputation as a centre for industrial innovation.

“GM’s decision to invest here speaks volumes about the talent of our workforce and the strategic importance of this location,” said a spokesperson from New York State’s economic development office. “This is not just an investment in engines, it’s an investment in people, in community, and in the future of American manufacturing.”

As GM works toward its stated goal of becoming an all-electric automaker by 2035, the Tonawanda investment demonstrates the company’s strategy to navigate a transitional period with a “both and” approach, pushing forward with EVs while supporting key legacy segments that remain profitable and in high demand.

“Electrification is the future, but combustion isn’t dead yet,” said auto industry analyst Caroline Marks of Autoview Research. “GM’s move reflects a practical understanding of market realities. Many fleet buyers, rural customers, and performance enthusiasts still value the power, range, and familiarity of gas-powered trucks and SUVs.”

Production of the new sixth-generation V-8 engines is scheduled to begin in 2027, aligning with model refreshes expected across GM’s larger vehicle lineup. While the company has not yet revealed specific performance metrics, insiders suggest the engines will deliver improved torque, better thermal efficiency, and greater adaptability for hybrid configurations, potentially serving as a bridge between traditional powertrains and future electrified systems.